We robotically weld the following materials:

We are holders of several welding A tests, including EN 1090 and SIST EN ISO 3834.

We are certified according to the ISO 9001: 2015 quality standard.

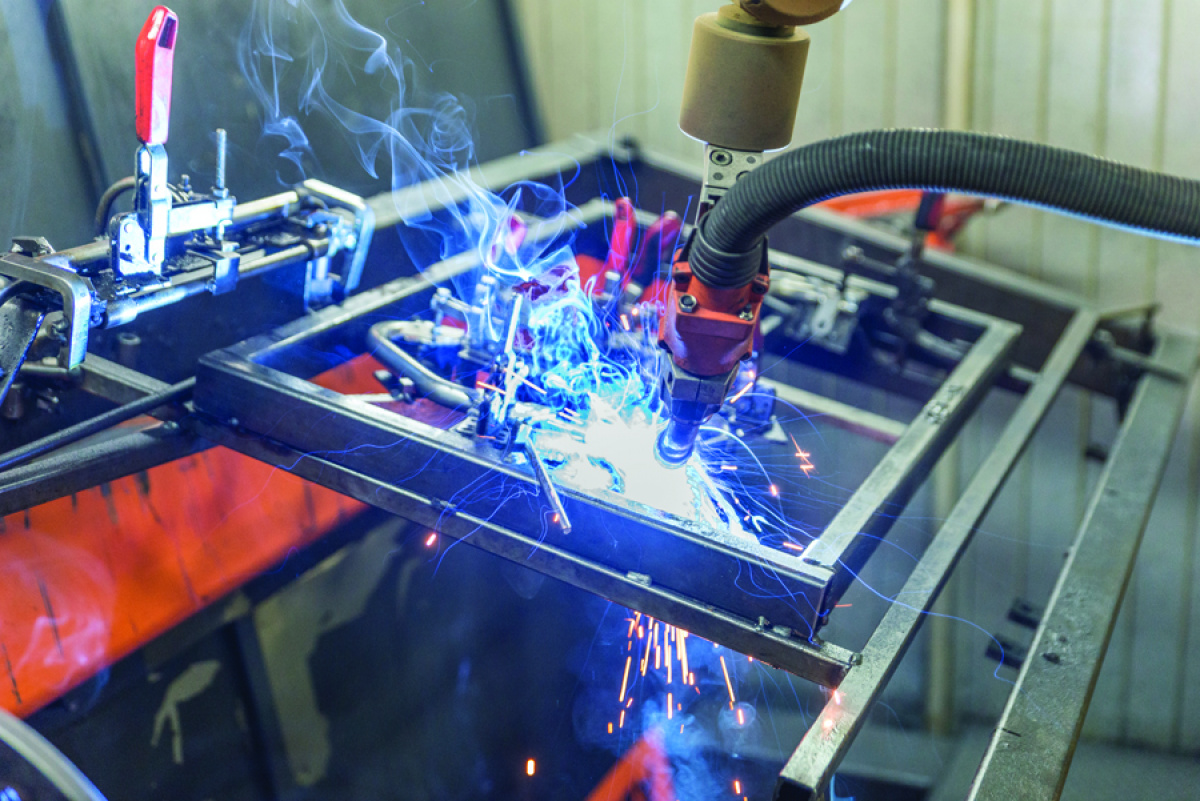

Our technologies enable precise welding of materials with optimal welding time. We offer the MIG / MAG robotic welding service in three robotic cells: two Yaskawa robotic cells and one ABB robotic cell. With these, we can produce larger quantities of the same welded constructions extremely quickly and accurately.

The first Yaskawa robotic cell is equipped with a single-axis positioner WG-250 on which we weld with a 6-axis welding robot Motoman MA2010.

The second Yaskawa robotic cell is equipped with a two-axis positioner DK-250 on which we can weld with a 6-axis welding robot Motoman MA1440 and MA2010.

Technical details of the Yaskawa robotic cell:

Max. workpiece diameter: 1600 mm

Load capacity: 250 kg

Max. range: horizontal 2010 mm; vertical 3649 mm

Repeatability: +/- 0.08 mm

Technical details of the ABB robotic cell:

Max. dimensions: 2000 x 1000 mm

Load capacity: 250 kg

Repeatability: +/- 0.06 mm

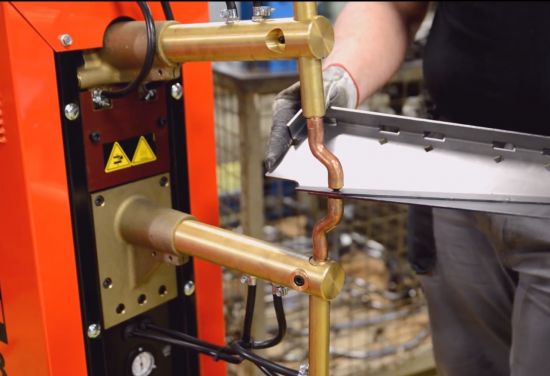

For easy joining of sheet metal parts, we offer spot welding. The process in which a spot weld is formed by means of two heated copper electrodes is mostly used for welding bodywork in the automotive industry and welding tanks.

We offer spot welding service on the Telwin PCP 18 and PEI Point PFB 136 welding machines.

Below are the technical details:

We offer TIG manual welding for welding of thin stainless steel and aluminum, magnesium and copper alloys. In this way, our experienced welders have complete control over the weld and can make it stronger and of better quality.

Compared to spot welding or MIG / MAG welding, the TIG process is more complex and slower and can only be performed by highly qualified welders.All our welders have welding certificates.

We also have an in-house certified IWE engineer who oversees the welding.

Manual welding is performed on three welding tables measuring 2000 x 1000 mm, where we can also weld products of larger dimensions that cannot be welded in robotic cells.