Quality control

Five key control points

1. We prepare a work order (WO), for each phase of work, to keep records of the quantity of manufactured pieces, the work time and the worker's performance.

2. After each phase, the product is controlled visually and measured. Each WO is also contains a drawing of the product.

3. Each phase controls the previous phase.

4. Before packing every single product is checked by the head of packaging department.

5. The final inspection it is carried out and the control sheet signed by the production manager.

Our management is able to see at any time in which phase the product is and how many have been made, thanks to the work orders in digital form. This also enables a fast action in case of failures or adjustments. Employees have regular annual training on production process and control.

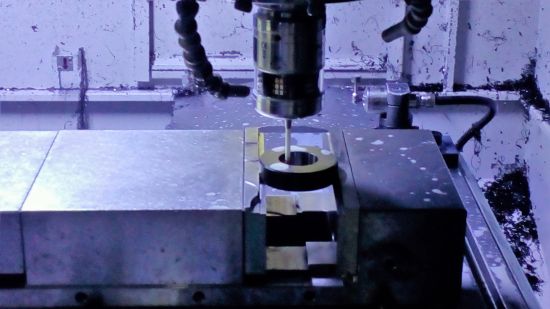

Top product depends also on cutting-edge tools and their maintenance. We regularly perform and record control checks of all machines and systems.

We take care of complete order processing. Any feedback from our customers is documented. We are striving to continuously improve quality.

In case of complaints, the 8D complaints system is carried out. We respond to any complaint within five working day.

Our primary concern is to fulfill the need of the customer to obtain a replacement product as soon as possible. Each error is analyzed and appropriate measures are implemented to ensure, that event does not repeat.