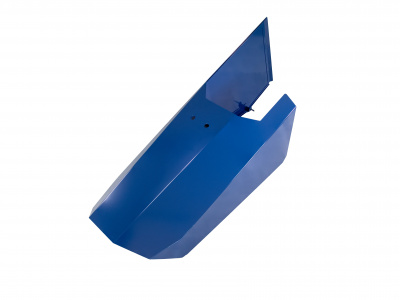

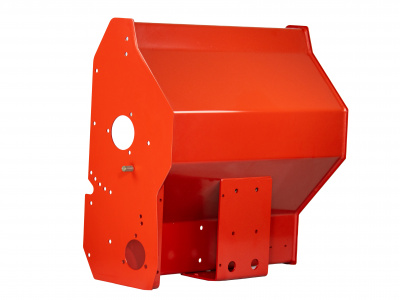

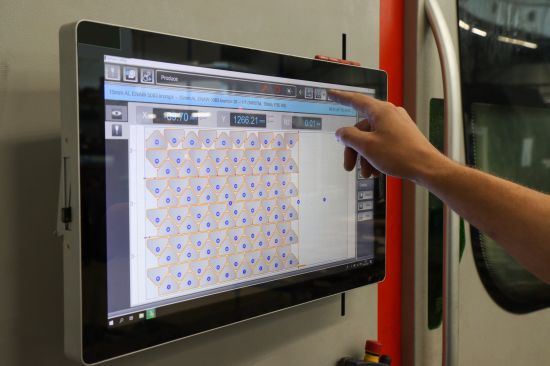

Our laser cutting services are done on Bystronic ByStar Fiber 6000.

The work surface area is 3000 x 1500 mm. We can achieve precision of +/- 0,1 mm.

We can offer processing of the following materials and thicknesses:

•Structural steel: up to 25 mm

•Stainless steel: up to 30 mm

•Aluminum: up to 30 mm

•Copper: up to 12 mm

•Brass: up to 15 mm

Laser can also be used for engraving identification numbers, positional markings, and processing of top layers of the material. The cut-out is based on a sketch or documentation in digital form.

The main advantages of fiber laser cutting are:

•High precision of the cut

•Most efficient utilization of material

•Cutting speed

•No additional tool costs

•Less energy consumption

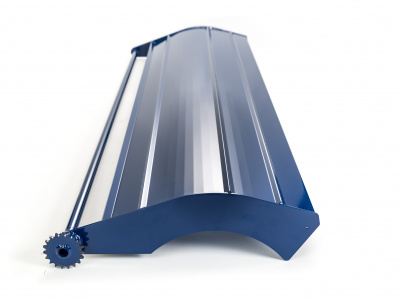

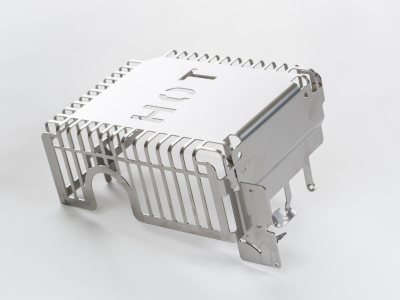

All laser-cut parts are machine-ground and deburred using the COSTA MD4 CV 1150 machine. This ensures that all pieces are completely safe to handle and suitable for direct installation.

Machine technical specifications:

Maximum workpiece width: 1,150 mm

Maximum workpiece height: 150 mm

Type of processing heads: two longitudinal abrasive units + one multifunctional unit with vertical brushes