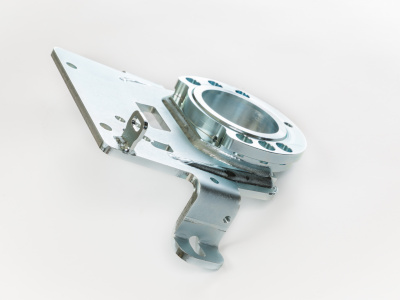

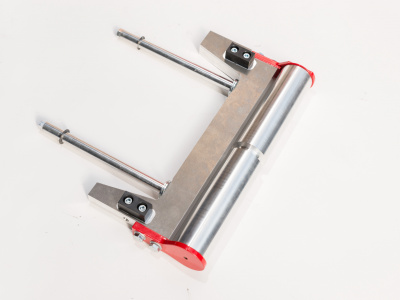

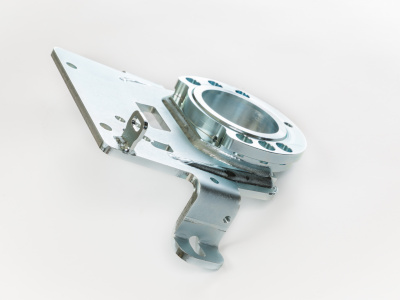

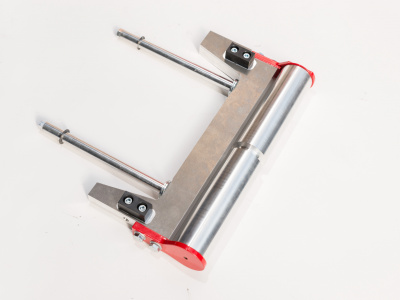

In our company, we use three CNC machining centers with three axes and driven tools.

All are equipped with the latest software solutions, allowing us to produce even the most demanding parts made of steel, stainless steel, aluminum, brass, and plastic.

We have machining centers of various sizes, ensuring efficient and precise processing of products according to their dimensions and complexity.

All centers are additionally equipped with an automatic feeding system, which increases productivity and machining repeatability.

The capabilities of each center are shown in the table below:

| Machine | Turning Diameter (mm) | Turning Diameter with Feeding System (mm) | Turning Length (mm) | Max Spindle Speed (rpm) | Number of Tools in Turret |

|---|---|---|---|---|---|

| Doosan LYNX 220 LM | up to ϕ320 | up to ϕ65 | up to 542 | 6000 | 12 (4 driven) |

| Doosan PUMA 3100 LY | up to ϕ420 | up to ϕ130 | up to 1285 | 2800 | 12 |

| Doosan LYNX 2600Y | up to ϕ380 | up to ϕ81 | 610 | 3500 | 12 |

Our vertical CNC machining center is used for coarse and fine machining. A powerful motor with an extremely precise base spindle enables high precision.

Milling capacity: